Capstan

Push it round.

Introduction

A capstan is a vertically positioned drum that is rotated by either human, steam, diesel, hydraulic, or electric power. Around the drum one can wrap a line and pull it with a lot more power than a man can do with just his hands.

History

On the first sailboat's lines where pulled straight with the hands, maybe a single rudimentary block and tackle was used to gain a mechanical advantage, but with the sizes of the boats that was hardly necessary.

No one can tell for sure when the first windlass was invented, whether it was on a boat or in a building. But the first designs where horizontal placed logs supported on either end. A line was wrapped around the middle. They were turned by bars slotted in the sides, usually both ends had a minimum of two holes. The bar was inserted into the top hole and pulled down ninety degrees. Then another person on the other side of the windlass would insert his bar in the top hole and start pulling. The first person would remove his bar as it could not pass underneath, and wait for the second person to make a quarter turn and then insert his bar again. Not only where these windlasses used on boats, but they were also used in castles to raise drawbridges and portcullises.

From these windlasses with a horizontal axle, the capstan with a vertical axle evolved. The advantage of the vertical one being that the bars for rotating did not have to be removed and inserted back again. And one could push rather than pull. Also capstan’s could have multiple people pushing simultaneously, greatly increasing their use. On the biggest capstan’s in the age of sail, their vertical axes passed through the deck, having sailors pushing on two decks simultainiusly. Their numbers could reach as high as 260.

Psst do you want to know more about ship's cats? Click here.

Working

The first capstans were simple wooden drums with holes for the bars and ribs to increase friction on the rope that was pulled. Near the bottom ratchets were placed to prevent back turning. These were simple designs and relied on weight to catch the slots in the baseplate. Lifting these ratchets up and turning them over allowed for the capstan to work the other way round.

The bars used for pushing numbered between two and sixteen. The bars are secured in place by running a rope around the outer ends of them, creating a circle.

With technological advancement also the capstans where developed. Instead of being of wood, they became of steel. And after that, they even had gears inside them that allowed a mechanical advantage. The drum would turn slower, but gain in torque. The most evolved once that still relied on human power even had switching gears, by turning the other way the gears would change.

As soon as steam power became widespread on board of ships, capstans became powered by steam as well. First, their design still featured the holes that allowed the bars to be slotted in, as a back up, but these soon disappeared.

After steam came hydraulics and then electricity. And some capstans are even powered by diesel engines.

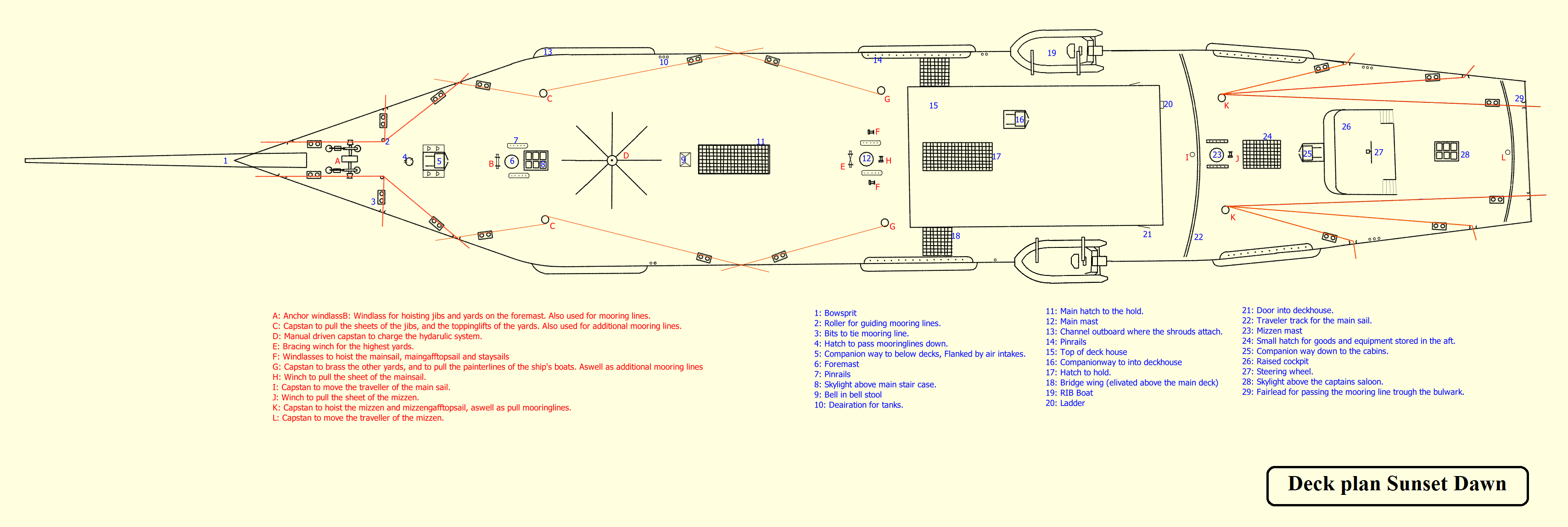

Capstans, winches and windlasses on the

Sunset Dawn

The Sunset Dawn is equipped with several capstans, winches and windlasses, most of them to handle lines for sail handling. But also for anchor lifting and tightening mooring lines

From fore to aft.

Capstan vs Winch vs Windlass

A capstan is a drum or spill with a vertical axle. Rope or chain is pulled with it and wound around it a single to a few times but not stored on it. A winch and windlass are drums or spills on a horizontal axle. The drum on a winch is used to pull and store rope or chain. The windlass is only used to pull the rope or chain.

Nice article! It was cool to read more about how those capstans work after seeing so many of them in harbours :D And I had not thought about how the lines for the sails were handled on the Sunset Dawn, but it makes a lot of sense that there are motors to help dealing with them rather than doing everything by hand like in the old days XD

Thank you.

Well it was your challenge that made me think and decide how the Sunset Dawn worked on this subject. :)