Utility Arms

Besides the iconic large, colorful, and emotive optics of MAI, the utility arms that they posess are probably one of their most notable features. It's not really much of a question what sparked their creation - living things need arms to interact with the world, right? But what inspired the first designs? What kinds of utility arms are out there? What's the styleability? Mod-ability? The possibilities are near endless, but still, some summarizing might be nice.

Initial Creation

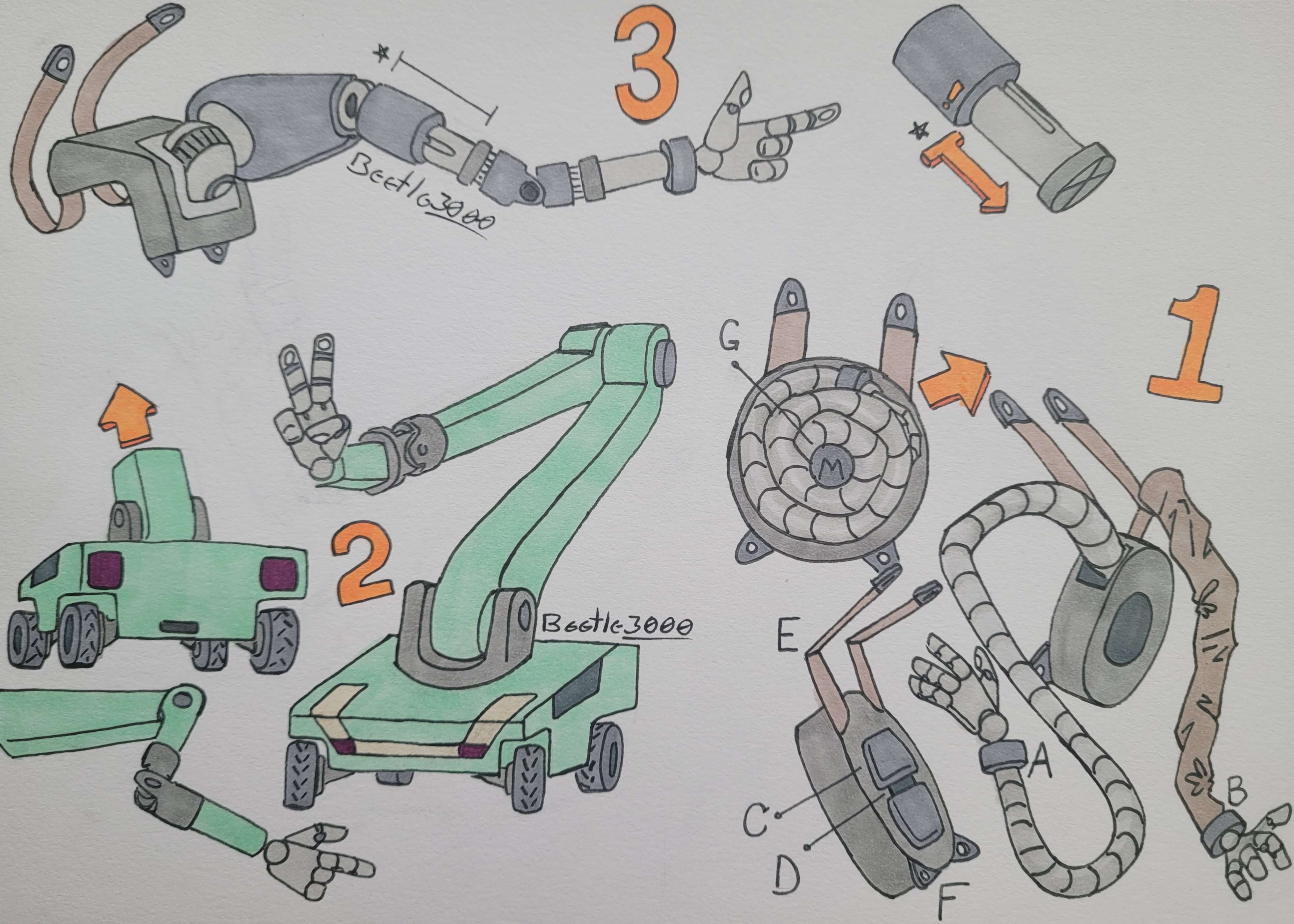

Amazingly enough, the very first prototype MAI, Aristophanes, wasn't actually fitted with arms upon activation. It was only after his handlers and caretakers saw his willingness to interact with objects that anyone had the thought occur to them, "Wait a minute... not having any arms doesn't make sense? Even if this is a tank?" so naturally, the beginning of utility arm design went underway. The first model ever finalized was what is known as a harnessed temp-mount tri-joint, which would later be known as a mini-temp for short. Essentially, about as simple as a robotic arm could be: a base that could be mounted to the side of the unit with buttons and harness straps, a shoulder joint, one elbow joint, a wrist joint, and the hand. Standard issue for all active service MAI, this was vastly the most common type to encounter for a long time. It may not have been particularly strong or had any considerable range of reach, but beyond that, it did just about whatever one would really need an arm to do. Thus, it was from here that most all further development of utility arms would stem.Mounting/Integration Methods

While there do exist MAI - True Vessel units specifically - which already have arms engineered into their frame, this article only refers to units that need utility arms from an external source in order to function. In general, there are considered to be two main methods by which an LAI can integrate and use a set of utility arms if they have none already: temp/harness-mount and drive-along. Temp and harness-mounts are often lumped in the same category, since harness is by far the most common way for temporary utility arms to be affixed to the vessel. Referring to the primary visual graphic, harness-mounts are depicted in sections 1 and 3. For the sake of standardization, harnesses are usually configured with two straps on the top that will anchor to mounting points installed on the top/near top of the vessel, and there are two strapless bottom snaps that will affix to similar points on the vessel's side. Harness-mounts are generally desirable in the fact that they take up little space and are easier to store. The primary downside however, especially for aircraft, is that permanent mounting studs must be installed on the exterior of the fuselage or hull in order for most models to be usable. Harness mount arms are normally strong enough for most applications, but MAI in jobs that require heavier lifting may find them to be insufficient - the arm can only be as strong as the harness that holds it in place. This is where drive-along arms may begin to be considered. Drive-along arms, as depicted in section 2 of the primary graphic, are exactly what they sound like. Rather than trying to affix the arm to the hull or fuselage, the arm simply gets its own mobile base from which to follow the unit. While this setup is much bulkier and possibly awkward to maneuver with in small spaces, the advantage is that drive-along arms are considerably stronger than temp-mounts.Joint types

In addition to mounting types, there is actually quite a great variation in the joint types that utility arms can have.Low-count Joints

As the most common and widely available joint-form, low-count joints are about what you'd expect a standard robust robot arm to look like. Referencing the primary figure, sections 2 and 3 depict low-count joints. If you recall above, a tri-joint arm has already been mentioned. Although for a while that was the most popular joint setup by way if it being a standard issue military product, the most popular configuration in modern times is actually the quad-joint arm, which is what the graphic depicts. Especially for drive-alongs, the quad-joint is preferable because it essentially allows for a convential human arm configuration that's lifted to the hight of the MAI by an additional segment. For harness-mounts, quad-joints are particularly popular with tanks because they tend to allow a greater range of reach over the multiple surfaces of the hull. Due to the fact that the range of reach these arms posess can be limited at times depending upon the situation, some producers have introduced an additional feature called adaptive-length segments. As shown in section 3, some solid limb segments can be extended or retracted by most often hydraulic or electronic means. Although this additional feature isn't seen as worthwhile by all utility arms users, it still has its own fairly dedicated userbase.Poly-joint

If you've ever seen a cartoon that includes robots or other mechanical sci-fi elements, you proably are already quite familiar with this type of arm! Colloquially given the title, "snake arm" or "noodle arm," poly-joints are a type of lightweight and densely articulated arm that's favored for its maneuverability and compact nature. Depicted in section 1, you might notice that this one garners a quite thorough explanation. Starting with legends A and B, there are two main visual styles for poly-joints; uncovered and covered. Although it's not absolutely necessary, some MAI prefer covered arms for their anti-pinch cloth that makes interacting with humans, other living things, and soft objects safer. The cover cloth also keeps the joints free of debris and reduces maintenance. Units that prefer the uncovered arm often work in environments that regularly expose them to moisture, or often gets them dirty. A lack of covering reduces moisture retention and makes the arm easier to clean when it inevitably does get dirty. Legends C and D point to the back side of the vessel-mounted housing. More specifically, C points to the padding that works as a buffer between the housing and the vessel, while D points to the removable backplate that covers the internal winching system - which is, yes - how the poly-joint is contracted when not in use. Looking at legend G, it points to the internal winch motor in the center of the arm, and its broader graphic shows how the arm is stored inside the housing. Like mentioned before, harness mounts have a strap and button system on the top and a strapless button system on the bottom; the legends E and F highlight this, and a similar setup is depicted in section 3.Branch Limb Configuration

The least often encountered type of utility arm joint, branch limbs, also called "wishbones," or "tees," are normally reserved for specialized work that requires both stability and considerable hands-on interaction. It's rare to see these arms as poly-joints since it's more difficult to add branching segments to them, so low-counts are normally the way to go for most users. The most common variation of branch limbs will have the branch at or near the last elbow closest to the wrist, and there will more often than not be a "dominant" limb that is proportional to the whole arm, and then one or more "secondary" limbs that are smaller. While they can be produced as either harness-mounts are drive-alongs, harness-mounts tend to be preferable since these arms are more often used for lighter work and the additional bulk is unnecessary.Utility

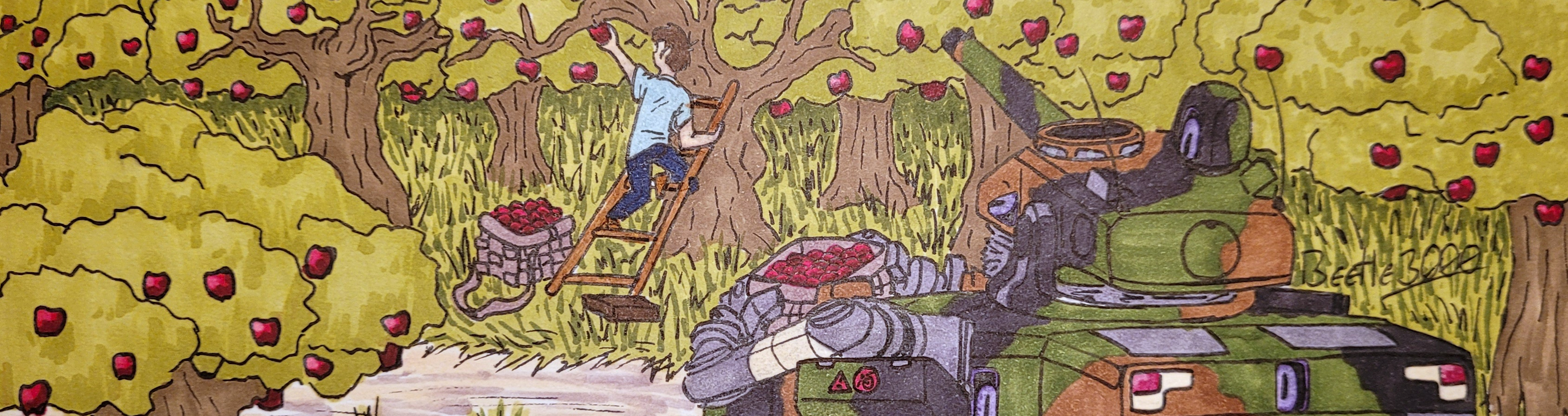

This tool is mainly used as, well, an arm. Since some LAI and MAI weren't made with them, it's certainly helpful to have a pair at the ready whenever you need them. While certain types of LAI certainly have their preferences, there's pros and cons to each type of limb that may compel and MAI to favor one over the rest. For example, hobbies, careers, the environments they live in, etc.

Access/Availability

Base pairs of utility arms are always covered under universal healthcare if the unit isn't equipped with any by default, but the purchase of additional pairs is not. These are made to be very readily accessible to LAI whether it be for purchase of for rent. They can be found in facilities where they'd be useful to the bot in specific job situations, or are purchasable online or in stores centered around other modern tools and utilities.

Access & Availability

Standard issue to all units that require them, and easy to aquire additional sets for those who don't. Covered in full by healthcare or widely available for purchase.

Complexity

Varies by utility arm type, but most are still fairly mechanically complex.

Comments