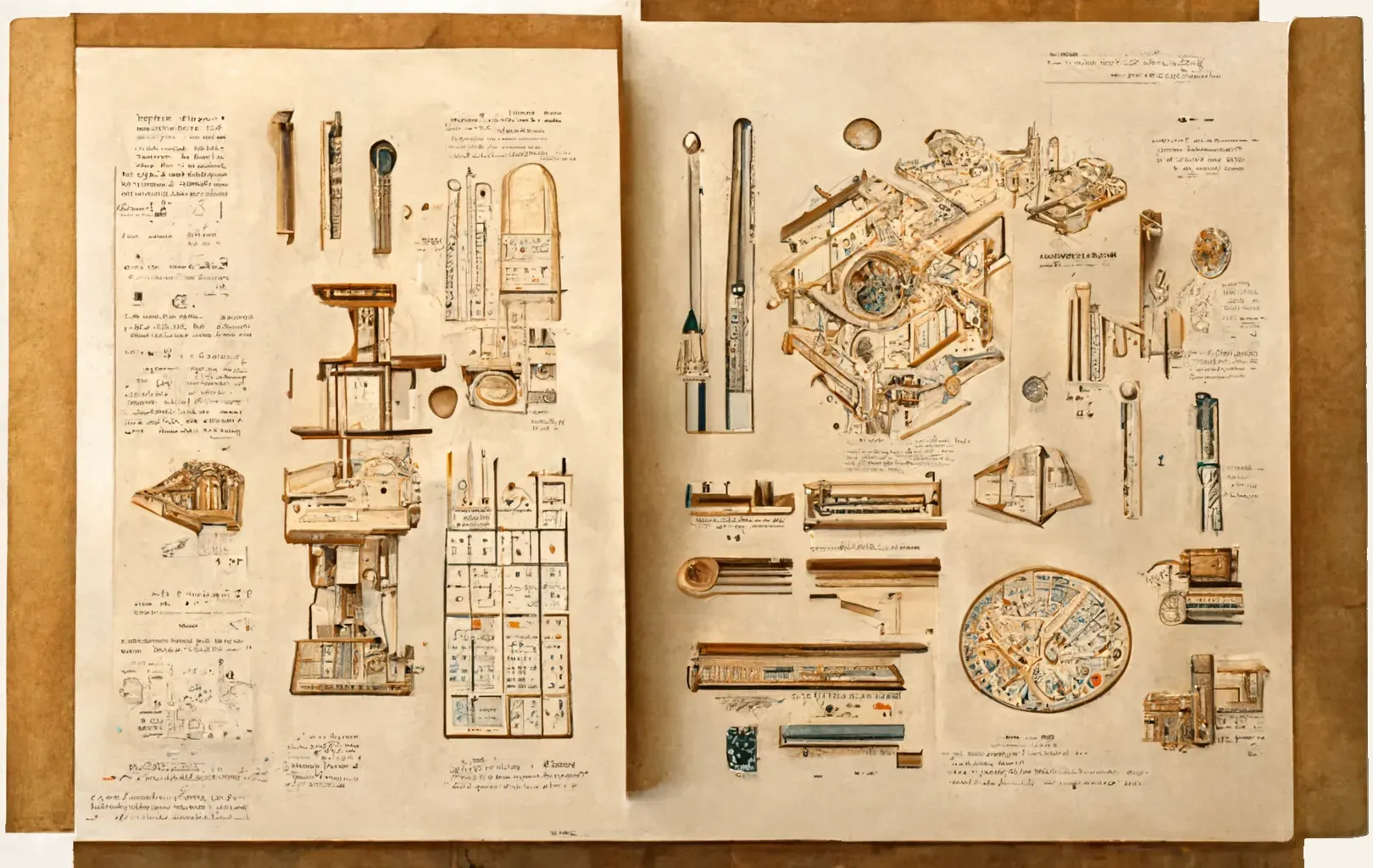

The Gnomius Imprimatur 2000 represents the pinnacle of gnomish engineering and craftsmanship, meticulously designed and manufactured by the talented minds at Gnome Workshop. This state-of-the-art printing press is a remarkable upgrade from its predecessor, packed with innovative features that make it the ultimate tool for producing high-quality, collectible cards.

Printing Press

Unlike previous models, the Gnomius Imprimatur 2000 boasts an integrated cutting mechanism, which has revolutionised the printing process, especially for Margo's collectible cards. Equipped with an array of adjustable precision cutting blades, the press can automatically cut sheets to exact specifications, from traditional rectangular shapes to more intricate designs. This streamlined functionality significantly reduces the need for manual labour, enabling high-volume production with unparalleled consistency.

Beyond its impressive printing and cutting capabilities, the Gnomius Imprimatur 2000 features a sophisticated quality monitoring system. This system continuously inspects each card during the printing and cutting process, scanning for any potential errors, misalignments, or imperfections. If an issue is detected, the system immediately makes real-time adjustments, maintaining the highest standard of accuracy and precision without halting production. The result is a flawless finish on every card, each one a miniature work of art.

Additionally, the press includes an “Artisan Mode” for limited-edition runs. In this mode, the machine slows down to allow for enhanced colour saturation and intricate details, making each print exceptionally vibrant and lifelike. Margo has even experimented with printing Geertruud-inspired collectible cards, each with intricate details that highlight various scenes from her friend’s storied adventures.

"Do you hear that? Tentacle Press is making books again. That noise, keeping us awake all night. And then tomorrow, the book is keeping us awake."

Infusion Sets

For creating a working infusion set, the following items are required:

Fixation Unit

The fixation unit is a thin board (for maps) or a book (for books) used as a carrier for

blueprints.

Blueprint

Blueprints are thin sheets of paper that get glued onto/into a

fixation unit.

Ink

This special magical ink is used to write or paint the content onto a

blueprint.

Fountain Pen

Used to write with

ink onto a

blueprint. Margo made a special magical version that allows her to dictate her texts.

The inked blueprints are carefully adhered to the fixation unit, which is designed to match the shape of the final product - whether that be a flat board for a map or an empty book for a publication. Once the blueprints are securely in place, the fixation unit is inserted into the printing press, where its contents are transferred to an empty map or book situated in a second slot of the Apparatus Gnomicus.

This entire process is impressively efficient, taking roughly nine minutes to produce a map and about twenty-four minutes for a book. However, the most time-consuming aspect of the operation is the manual task of pulling levers and pushing buttons to initiate the printing sequence. When two skilled gnomes work together as a team, they can dramatically reduce this downtime to just a minute. This teamwork enables them to print up to five maps per hour - about ten minutes per map, fitting nicely within a 50-minute work period, followed by a mandatory ten-minute snack break as stipulated by the Labour Union of Working Gnomes. They can also produce two books per hour, optimising productivity while adhering to labour regulations.

While the Apparatus Gnomicus excels at the printing process, preparation of the empty maps or books must still be done by hand. This involves carefully aligning each sheet and ensuring the quality of materials, which adds a bit of traditional craftsmanship to the otherwise mechanised process.

To keep the Apparatus Gnomicus running smoothly, it requires a minor maintenance cycle every eight hours. This routine upkeep includes refuelling ink, greasing moving parts, and cleaning away any accumulated dirt and debris. Once a month, a more extensive maintenance cycle is necessary, which involves replacing worn-out parts and conducting a thorough inspection to ensure everything is functioning optimally.

Printing Press Construction Plans

Poor Margo, having to jump on her levers or having to hang from them XD

She's also a wizard, she might use that, aaand there is the octopus Rupert there to help when help is needed. :D