Heavy Freight Wagon

Heavy freight wagons are a common sight along the trade roads of both the Northern and Southern Kingdoms, where they are primarily used to transport cargo and agricultural products. Favored by farmers, who use the large wagons to move grain to better paying markets in or near the larger cities, these wagons are also used by traveling merchants, transport companies, and even families moving to new areas. Known for a study build and a design that reduces the shifting of cargo, even over the most rugged of terrain, the heavy freight wagon has been one of the most popular wagons since it first came into use.

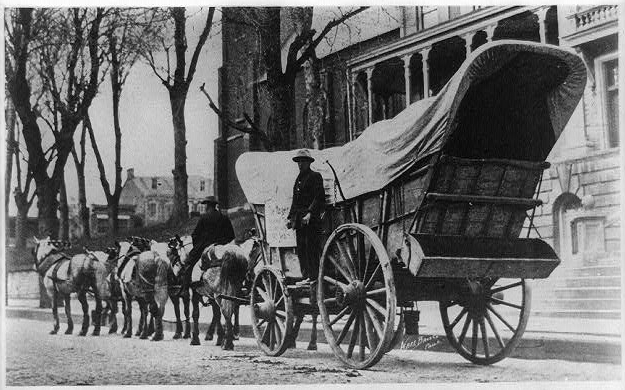

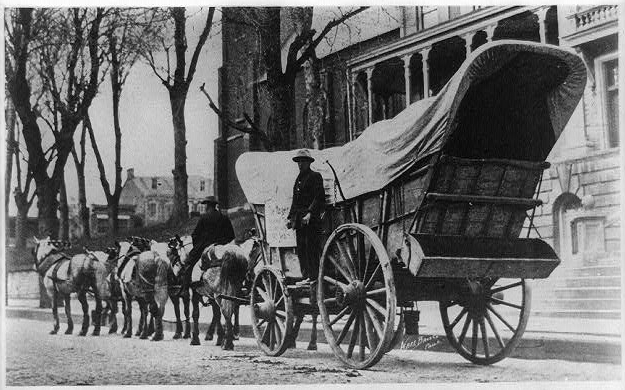

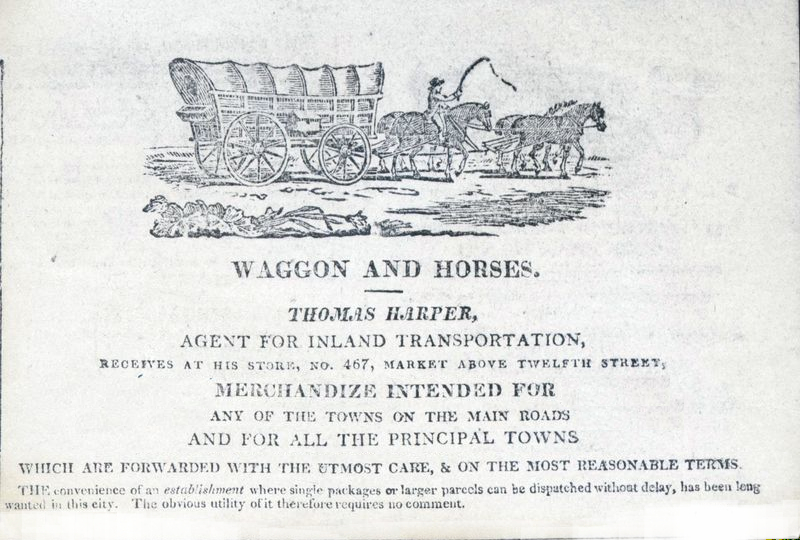

A heavy freight wagon preparing to set out from the city of Newcastle.

Built by the shipwrights of the Northern Kingdom's crown city, the heavy freight wagons are the primary means of overland freight transport not only in the Kingdom of the North, but the sturdy wagons have, over the years, come to be prized by the people of the southern kingdom as well.

The seaside cites of the Southern Kingdom have the most heavy freight wagons per capita than any other city in either kingdom. This is credited to the suitability of their sturdy build for the transport of cargo from warehouses or factories to the ships in the port, and goods from ships to warehouses, factories, and seafood processing facilities. It is estimated that roughly 32%-47% of the wagons in port cities of the Southern Kingdom are heavy freight wagons, used to haul whales and whale products to refineries and processing facilities.

Originally constructed by men that had worked as shipwrights, the wagons were built to be strong enough to weather storms, cross rivers, and arrive with their cargo intact. Curved bottoms, reminiscent of the shape of a ship, stabilized the cargo over long distanced and rough travel. Many are sealed with tar to protect the cargo from water when the wagons ford waterways and there have been reports of heavy freight wagons being converted into barges to move items along roads, down rivers, and across lakes.

Covered Wagon - Conestoga by Ware Bros. Co, photographer. (ca. 1862)

First Use

The heavy freight wagon was first put into use not long after Newcastle was settled. The first ones were built by shipwrights at some point before a reliable means to reach the sea, some 200 feet below the city, was devised. The heavy freight wagons were constructed for hauling goods from the growing city of Newcastle, across the vast grasslands of the high valley region, then over Crown Pass in the Crown of the World mountains, and down into the low open lands of the Southern Kingdom. Hailed as a wagon that could traverse any terrain, even cross rivers and lakes, the heavy freight wagon has been in steady production and use as an overland freight hauler ever since it was first put into use with little having been changed from the wagon's original design.Modern Design Changes

More modern designs have favored a more compact frame with the bows pulled inward to allow the wagons better maneuverability in the mountains and along more narrow forest pathways. Smaller scale versions of the heavy freight wagons, without the bows and canvas covers, are built for use in mines where they are pulled by teams of ponies or donkeys.Specifications

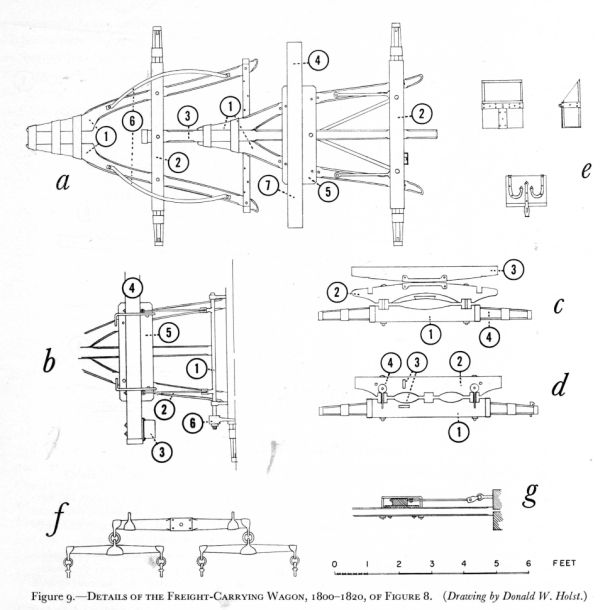

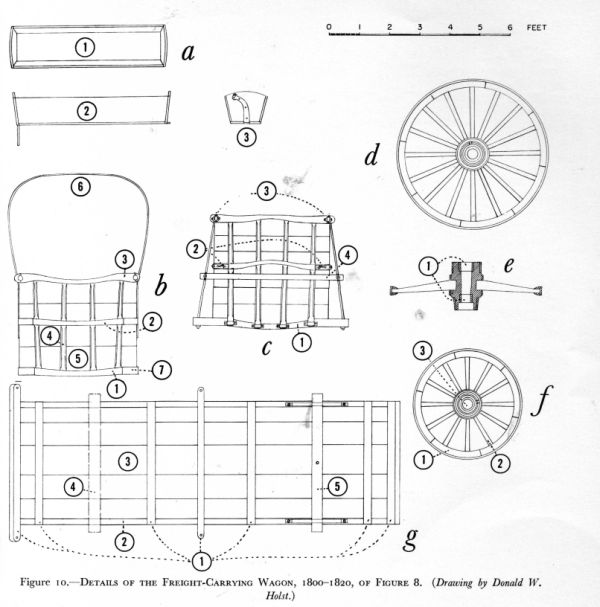

Source: CONESTOGA WAGONS IN BRADDOCK'S CAMPAIGN, 1755 by Don H. Berkebile a: Bed and running gear, right side: 1, Bows for supporting cover. 2, Ridgepole, or stringer. 3, Top rail, with bow staples and side-board staples. 4, Side-boards, removable. 5, Feedbox in traveling position. 6, Rubbing plates to prevent wheels wearing wooden frame. 7, Side-board standards, forming framework of sides (on the inside, a few of these sometimes project a few inches above the top rail to support the side-boards). 9, Securing rings for the ends of the spread chains, two of which span the bed to give extra support to the sides against inside pressures. b: Tongue, or pole, top and side views: 1, doubletree hasp, shown in proper position over the doubletree in the lower drawing: the hammer-headed doubletree pin goes through it, then through the doubletree and the tongue. 2, Wear plate for doubletree pin. 3, Feedbox staple; in use, the feedbox is unhooked from the rear, the long pin on one end of the box is passed through the hole for the doubletree pin, and the lug on the other end of the box is slipped through the staple. 4, Hitching rings, for securing horses while feeding. 5, End ring. a: Running gear, top view: 1, Front and rear hounds. 2, Bolsters, with axletrees directly underneath. 3, Coupling pole. 4, Brake beam. 5, Brake-beam shelf, or support. 6, Segments forming the fifth wheel; these prevented the bed from toppling, or swaying excessively on turns. 7, Rear brace for front hounds, to keep tongue from dropping. b: Brake mechanism, detail: 1, Brake rocker bar, with squared end for brake lever. 2, Rods connecting rocker bar to brake beam. 3, Rubber, or brakeshoe, made of wood, often faced with old leather. 4, Brake beam. 5, Brake-beam shelf, or support. 6, Brake lever, often 4 or 5 feet long. c: Front axletree and bolsters, front view: 1, Axletree. 2, Bolster, showing wear plates. 3, Upper bolster, actually part of the wagon bed. 4, Axle, showing ironing. d: Rear axletree and bolster, rear view: 1, Axle tree, showing linchpin in position in right axle 2, Bolster. 3, Hook and staple for holding bucket of tar used in lubricating axles. 4, Hound pins. e: Toolbox, showing front, end, and top; it was secured to left side of wagon. f: Doubletree, with singletrees attached. g: Brake mechanism, side view. a: Feedbox: 1, Top. 2, Side, showing pin and lug for securing to tongue. 3, End, showing bracket into which the chains hooked for traveling. b: Front end panel: 1, Bottom end rail. 2, Middle end rail. 3, Top end rail. 4, Standard, or upright, forming end framing. 5, End boards. 6, Bow. 7, Corner plates. c: Rear end gate: 1, Staples for end-gate standards. 2, End-gate hasps and hooks. 3, Pins to secure gate to upper side rails. 4, Crossbar to give extra support to end gate. d: Rear wheel. e: Cross section of wheel: 1, Boxings, of cast iron, wedged in hub to take wear of axle. f: Front wheel: 1, Felly, or felloe. 2, Spoke. 3, Hub, or nave. g: Floor of wagon, from under side: 1, Crossbeams, the center and rear ones being heavier, and projecting at the ends to hold the iron side braces visible in figure 8,a. 2, Bottom side rails. 3, Floorboards. 4, Position of rear bolster when bed is on running gear. 5, Front bolster, showing hole for kingpin.

Wagon by H. Langden Brown

A long narrow wagon with a curving frame style design that prevents the shifting of cargo during long hauls.

Most Often Used to Transport corn, barley, and wheat from distant farms to markets in the cities.

Wheels

Front: 3.5 feet across, 2.5 inches wide

Rear: 5 feet across, 3 inches wide

Built in a concave shield-like style.

Cargo Rates Charged:

Roughly one dollar per 100 pounds per 100 miles

Most Often Used to Transport corn, barley, and wheat from distant farms to markets in the cities.

Wheels

Front: 3.5 feet across, 2.5 inches wide

Rear: 5 feet across, 3 inches wide

Built in a concave shield-like style.

Class

Used by

Nickname

Land Ship, or Ships of the Land.

Beam

4 feet

Length

16 feet at the bed, 26' along the top of the bows.

Height

11 feet (4 foot tall sideboards)

Weight

(Varies based on type of wood and amount of metal used in construction.)

Speed

Average 12 to 15 miles per day.

Complement / Crew

A single driver, or a two man team

Team of four to six horses

[Alternately: four to six centaurs]

Team of four to six horses

[Alternately: four to six centaurs]

Cargo & Passenger Capacity

Up to 12,000 pounds (5,400 kg) of weight

Brakes Optional

Because of the increase in weight, and their general ineffectiveness, brake systems are not standard on heavy freight wagons. Buyers may request their installation at additional cost when a wagon is to be built, or have them installed on wagons that were purchased without brakes. Most drivers prefer to use chain-locks or drag poles. Another method used to prevent wagons from moving is to slide a log through the spokes of the wheels. Chain Lock The chain lock is one of the easiest methods to prevent a wagon from moving and is a simple matter of slipping a length of chain through the spokes of the wheel and securing it on a hook on the side of the wagon. Chalks or Wheel Shoes Angled pieces of wood, metal, or stone, that is positioned on the down-slope side of a wheel, or on both the font and back of a wheel, to prevent it from rolling. Double Team or Winch Teamsters often hitch a second team to a wagon when it needs to ascend or descend a steep slope, such as the road up and down the Crown of the World Mountains. Winches, come alongs, and more traditional block and tackle systems, are occasionally used to help slow a wagon's descent or pull a heavy load up a slope.Remove these ads. Join the Worldbuilders Guild

Comments